Man does not buy garments for temporary or one time used. When we use garments they become dirty and needs to washed off. All types of garment should not wash with general soap or detergent. Some garments need not wash, they are typically dry cleaned and some are washed but not apply in chlorine bleach or any other solvents. Water temperature is also another factor for garment washing because there might be some decorative elements which will be destroyed. So garments should be washed with the specific care instructions suggest by the seller normally.

To take care of garments there are some symbols and details which are recognized internationally and they are used in garment care labels. These symbols are usually known as garment care labeling code or symbols.

At a minimum, laundering instructions include, in order, four symbols: washing, bleaching, drying, and ironing. Dry cleaning instructions include one symbol. Additional symbols or words or both may be used to clarify the instructions. The water temperatures listed are provided as a guideline. Actual water temperatures obtained in the home depend on the washing machine settings (hot, warm, cold), regional water supply temperatures, and water heating settings.

To assist consumers in getting information about clothing care, the Federal Trade Commission in 1971 issued the Care Labeling Rule. This Rule requires manufacturers and importers to attach care instructions to garment. A revised version of this Rule became effective on January 2, 1984. The revisions to the Rule were based on information gathered by the Commission through public hearings and written comments. Data revealed that while consumers found care labels to be useful, they also believed labels were often incomplete, inaccurate, and inconsistent.

The revised version of the Rule makes no major modifications. rather, the changes clarify the Rule requirements and simplify the Rule language. The Commission anticipates that these changes will make it easier for industry to comply with the Rule. In turn, consumers will benefit from clearer and more complete care instructions.

Care labels often are a deciding factor when consumers shop for clothing. While some are looking for the convenience of dry cleaning, others prefer the economy of buying garments they can wash. Some manufacturers try to reach both markets with garments that can be cleaned by either method. The Rule allows you to provide more than one set of care instructions, if you have a reasonable basis for each instruction.

The Federal Trade Commission has developed this business manual to assist you in understanding and complying with the Rule. If you have questions not addressed in this booklet, write to the Federal Trade Commission, Enforcement Division. Bureau of Consumer Protection, Washington, D. C. 20580.

Wash Care Symbols and Details

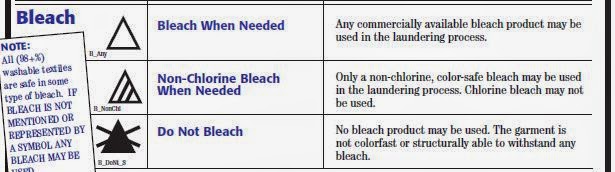

Bleaching Care Symbols

Drying Care Symbols

Dry Cleaning Symbols

Ironing Symbols

International Wash Care Instructions Used in Garment | Home Laundering and Drycleaning Symbols for Clothing

Advertisements

Man does not buy garments for temporary or one time used. When we use garments they become dirty and needs to washed off. All types of garment should not wash with general soap or detergent. Some garments need not wash, they are typically dry cleaned and some are washed but not apply in chlorine bleach or any other solvents. Water temperature is also another factor for garment washing because there might be some decorative elements which will be destroyed. So garments should be washed with the specific care instructions suggest by the seller normally.

To take care of garments there are some symbols and details which are recognized internationally and they are used in garment care labels. These symbols are usually known as garment care labeling code or symbols.

At a minimum, laundering instructions include, in order, four symbols: washing, bleaching, drying, and ironing. Dry cleaning instructions include one symbol. Additional symbols or words or both may be used to clarify the instructions. The water temperatures listed are provided as a guideline. Actual water temperatures obtained in the home depend on the washing machine settings (hot, warm, cold), regional water supply temperatures, and water heating settings.

To assist consumers in getting information about clothing care, the Federal Trade Commission in 1971 issued the Care Labeling Rule. This Rule requires manufacturers and importers to attach care instructions to garment. A revised version of this Rule became effective on January 2, 1984. The revisions to the Rule were based on information gathered by the Commission through public hearings and written comments. Data revealed that while consumers found care labels to be useful, they also believed labels were often incomplete, inaccurate, and inconsistent.

The revised version of the Rule makes no major modifications. rather, the changes clarify the Rule requirements and simplify the Rule language. The Commission anticipates that these changes will make it easier for industry to comply with the Rule. In turn, consumers will benefit from clearer and more complete care instructions.

Care labels often are a deciding factor when consumers shop for clothing. While some are looking for the convenience of dry cleaning, others prefer the economy of buying garments they can wash. Some manufacturers try to reach both markets with garments that can be cleaned by either method. The Rule allows you to provide more than one set of care instructions, if you have a reasonable basis for each instruction.

The Federal Trade Commission has developed this business manual to assist you in understanding and complying with the Rule. If you have questions not addressed in this booklet, write to the Federal Trade Commission, Enforcement Division. Bureau of Consumer Protection, Washington, D. C. 20580.

Wash Care Symbols and Details

Bleaching Care Symbols

Drying Care Symbols

Dry Cleaning Symbols

Ironing Symbols

Advertisements